Hervorheben:

Filterbeutel-Staubabscheider

, Düngemittel-Pellet-Filterbeutel-Staubabscheider

Produktübersicht

Als führender Anbieter von Düngemittelgeräten bieten wir leistungsstarke Filtertüten und Staubsammler an, die für eine saubere Luft und einen effizienten Betrieb in Ihrer Düngemittelproduktion sorgen.

Hochwertige Filtertüten Staubsammlersind wesentliche Geräte zur Bekämpfung der Luftverschmutzung, die Partikel aus Industrieabgasströmen entfernen.wie zum Beispiel das SchleifenWir haben in unseren Baghouses Stofffiltertüten eingesetzt, um Staubpartikel einzufangen.die Freisetzung sauberer Luft ermöglicht.

Eigenschaften

- Hohe Effizienz: Aufnimmt bis zu 99,9% Feinstaub und gewährleistet die Einhaltung strenger Umweltvorschriften.

- Vielseitige Anwendung: Wirksam bei verschiedenen Staubarten und -konzentrationen, die häufig in der Düngemittelproduktion vorkommen.

- Dauerhafte Konstruktion: So gebaut, dass sie anspruchsvollen industriellen Bedingungen standhält und eine lang anhaltende Zuverlässigkeit gewährleistet.

- Skalierbarkeit: Geeignet für kleine Werkstätten bis hin zu großen Industrieanlagen mit unterschiedlichen Produktionsmaßstäben.

- Umweltfreundlich: Verringert die Luftverschmutzung, fördert eine sauberere Luft und hilft den Industriezweigen, strenge Umwelt- und Sicherheitsstandards einzuhalten.

- Kosteneffizient: Bereitstellung einer kostengünstigen Lösung für die Staubentsammlung mit geringem Wartungsaufwand.

Arbeitsprinzip

Staubbelastete Luft: Die staubbelastete Luft wird in der Regel durch einen großen Ventilator in das Beutelhaus gezogen.

Filtration: Die Luft fließt durch Stofffilterbeutel, die in Reihen angeordnet und vertikal im Baghouse montiert sind.

Staubentnahme: Staubpartikel werden auf der Außenseite der Filterbeutel eingeschlossen, während saubere Luft durch das Filtermaterial hindurchgeht und aus dem System austritt.

Reinigung: Da sich Staub auf den Beuteln ansammelt, nimmt der Druckabfall zu.bei denen kurze Sprünge Druckluft in die Beutel injiziert werden, um den Staub zu entfernen.

Staubentfernung: Der entfernte Staub fällt in einen Sammelhocker am Boden des Beutelhauses, wo er zur Beseitigung oder Weiterverarbeitung entfernt werden kann.

Warum man sich für einen Gofine-Taschensammler entscheidet

- Pulssprengreinigungssystem

Automatische Reinigung der Filterbeutel mit Druckluftpulsen, bei der optimale Filterwirksamkeit beibehalten und ein kontinuierlicher Betrieb ermöglicht wird.

Ermöglicht eine einfache Erweiterung oder Änderung, wenn sich Ihre operativen Bedürfnisse ändern.

- Integrierte Kontrollsysteme

Erweiterte Steuerungen überwachen die Leistung des Systems und stellen Warnungen und Diagnosen zur Verfügung, um Probleme zu verhindern, bevor sie auftreten.

- Weite Palette von Filtermedien

Sie können aus verschiedenen Stoffen und Oberflächen (z. B. Polyester, Aramid, Glasfaser, PTFE) wählen, um spezifische Staubarten, Temperaturen und Anforderungen an die chemische Verträglichkeit zu erfüllen.

Schwere Stahlkonstruktion für langlebige Leistung in anspruchsvollen Umgebungen.

Optionen für Explosionslüften und andere Sicherheitsvorrichtungen für den Umgang mit brennbarem Staub.

Entworfen für einen einfachen Zugang zu Filtern und anderen Komponenten, die Wartung vereinfacht und die Ausfallzeiten reduziert.

Anwendungen

Unsere Filtertüten Staubsammler sind ideal für verschiedene Anwendungen in der Düngemittelproduktion, einschließlich:

Schleifen und Fräsen: Abfangen von Staub aus Größenreduzierungsverfahren.

Mischen und Mischen: Kontrolle des Staubs, der beim Mischen verschiedener Düngemittelbestandteile entsteht.

Granulierung: Entfernen von Staub aus dem Granulationsverfahren.

Trocknen und Kühlen: Filtern von Staub aus Trocknern und Kühlgeräten.

Screening und Klassifizierung: Abfangen von Staub aus Screening-Aktionen.

Verpackung und Verpackung: Kontrolle des Staubs während der Befüllung und Versiegelung von Düngemittelbeuteln.

Produktparameter

| Kapazität für die Luftverarbeitung |

1,000-100.000 m3/h |

| Filtrationsluftgeschwindigkeit |

00,5-2,0 m/min |

| Eintrittsstaubkonzentration |

≤ 1.000 mg/Nm3 (höchstens 30 g/Nm3) |

| Staubkonzentration beim Auslaufen |

≤ 30 mg/Nm3 (nationale Norm) |

| Effizienz der Staubentfernung |

≥99% |

| Betriebswiderstand der Ausrüstung |

800 bis 1800 Pa |

| Filterbeutelmaterial |

Polyester/PTFE/Glasfaser/beschichtet |

| Methoden zur Staubreinigung |

Impulsausstrahl/Rückwärtsluftblasen/mechanische Vibrationen |

Zusatzgeräte

Um eine optimale Leistung und eine vollständige Lösung zu gewährleisten, bieten wir auch eine Reihe von ergänzenden Geräten für unsere Staubsammler im Baghouse an:

Rotationsluftschleusen: Zur kontrollierten Ableitung von Staub aus dem Hopfer.

Schraubförderer: zur Verbringung von Staub in Entsorgungs- oder Verarbeitungsbereiche.

Staubsammler: Für eine effiziente Staubsammlung und -lagerung.

Luftkompressoren: zur Bereitstellung von Druckluft für Pulssprengreinigungssysteme.

Kanalisation: zur Anbindung von Staubquellen an das Baghouse.

Steuerungspanele: Für die automatisierte Bedienung und Überwachung des Baghouse.

Ersatzfiltertüten: hochwertige Filtertüten, um eine optimale Leistung und Langlebigkeit zu gewährleisten.

Käfige: Zur Unterstützung der Filtertüten.

Kontaktieren Sie uns noch heute, um mehr über unsere Staubsammler zu erfahren und wie sie die Luftqualität und Effizienz in Ihrer Düngemittelproduktion verbessern können.

Einzelheiten zum Produkt

Weitere Modelle von Staubentfernungsgeräten

Über uns

Als Anbieter von landwirtschaftlichen Geräten mit mehr als zehnjähriger Erfahrung bietet Gofine Machine eine Vielzahl von Dienstleistungen an, um den Bedürfnissen der Kunden gerecht zu werden.

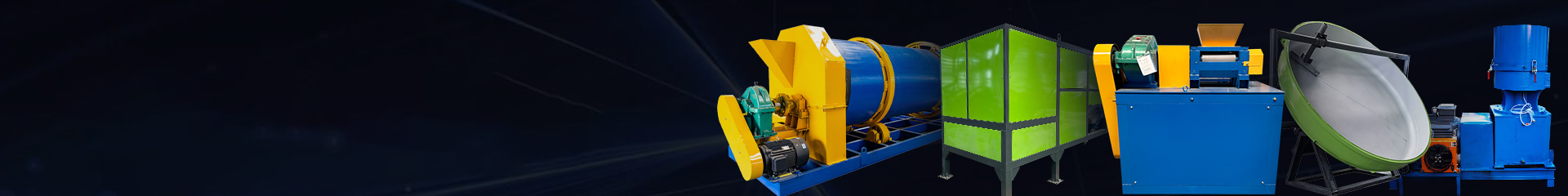

Bereitstellung verschiedener Arten von landwirtschaftlichen Geräten, einschließlich granulierender organischer Düngemittel, granulierender Zusammensetzung von Düngemitteln, granulierender anorganischer Düngemittel, granulierender wasserlöslicher Düngemittel,Düngemittelgranulatoren mit kontrollierter Freisetzung, Düngemittel-Sortierungsmaschinen, Zerkleinerer, Mischer, Trockner, Granulationsmaschinen, Beschichtungsmaschinen, Granulationsscreening-Maschinen, Verpackungsmaschinen und eine komplette Reihe von Düngemittel-Produktionslinien.

Wir bieten professionelle technische Beratung und Unterstützung, um Kunden bei der Auswahl der richtigen Geräte und Prozesse zu unterstützen und den Produktionsprozess zu optimieren.

- Installation und Inbetriebnahme

Bereitstellung von Anlageninstallations- und Inbetriebnahmeleistungen für Kunden, um den normalen Betrieb der Anlagen zu gewährleisten und die erwarteten Produktionsergebnisse zu erzielen.

Bereitstellung von Betriebsschulungen, um den Mitarbeitern der Kunden zu helfen, die Gebrauchs- und Wartungsfähigkeiten der Ausrüstung zu beherrschen und die Produktionseffizienz zu verbessern.

- Dienstleistungen nach dem Verkauf

Bereitstellung eines umfassenden Kundendienstes, einschließlich regelmäßiger Wartung, Fehlerbehebung und Zulieferung von Ersatzteilen, um den langfristigen und stabilen Betrieb der Ausrüstung zu gewährleisten.

Wir bieten personalisierte Ausrüstung und Produktionslinie-Design-Lösungen, die auf den spezifischen Bedürfnissen unserer Kunden basieren, um die Bedürfnisse der Düngemittelproduktion in unterschiedlichen Maßstäben und Arten zu erfüllen.

Durch diese Dienstleistungen verpflichten wir uns, unseren Kunden hochwertige Düngemittelgeräte und umfassende Unterstützung zu bieten, um ihnen zu helfen, auf einem sehr wettbewerbsorientierten Markt erfolgreich zu sein.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!