Ausrüstung für die Produktion von Düngemitteln ohne Trocknung: Doppelwalz-Extrusionsgranulator

Übersicht

Der Double-Roller-Extrusionsgranulator, auch als Trockengranulationsmaschine oder Roll Press Compactor bekannt, ist eine fortschrittliche industrielle Ausrüstung zur Umwandlung von Feinstaub in dichten,gleichförmige Granulate ohne flüssige BindemittelDiese Maschine nutzt die Roll Press Compaction Technologie, bei der zwei synchronisierte, gegenwärtig drehende Rollen einen extremen mechanischen Druck ausüben, um Rohmaterial durch präzise gestaltete Formen zu drängen.Das entstehende blattähnliche Material wird dann in einheitliche Granulate zerlegt.

Diese Granulationsanlage zeichnet sich durch die Verdichtung der Materialien aus und ist somit ideal für die Produktion von Düngemitteln, chemische Verarbeitung und Mineralagglomerationen geeignet.und skalierbare Lösung für die Umwandlung von Pulver in Granulat in kontinuierlichen Granulationsverfahren.

Wesentliche Merkmale

- Prozess der Trockengranulation:Produziert Granulate ohne Feuchtigkeit oder flüssige Bindemittel, wodurch Trocknungsschritte und Energieeinsparungen vermieden werden.

- Verdichtung von Hochdruckwalzen:Robuste Walzen mit hydraulischem/Federdrucksystem sorgen für eine hohe Kompression von harten, dichten Granulat.

- Ausgezeichnete Verdichtung:Vergrößert die Massendichte, verbessert die Speicher-/Transport-Effizienz und reduziert den Staub.

- Kontinuierlicher automatischer Betrieb:Hohe Durchsatzleistung mit stabiler Ausgabequalität und minimalem Eingriff des Bedieners.

- Vielseitigkeit:Verarbeitet Düngemittel, Chemikalien, Mineralien und Industriepulver mit anpassbarer Granulengröße/Form.

- Umweltfreundlich:Das geschlossene System minimiert die Staubbelastung und verhindert die Entstehung von Abwasser.

- Leichte Wartung:Hochverschleißbeständige Materialien sorgen für eine lange Lebensdauer und eine geringere Ausfallzeit.

Anwendungen

Der Double-Roller-Extrusionsgranulator dient mit seinen vielseitigen Fähigkeiten mehreren Branchen:

- Düngemittelgranulation:Produziert zusammengesetzte Düngemittel, NPK-Dünger und organisch-anorganische Mischungen aus Materialien wie Ammoniumchlorid und Kaliumchlorid.

- Chemische Granulation:Verarbeitet Pigmente, Farbstoffe, Harze, Pestizide und Insektizide, um die Durchflussfähigkeit zu verbessern.

- Mineral- und Metallindustrie:Agglomeriert Metallpulver, Feinkohle, Kohlenstoffschwarz und Erze für eine bessere Handhabung.

- Pharmazeutische/Lebensmittelindustrie:Ermöglicht die Trockengranulation für Pulverformulierungen, die eine verbesserte Kompressions- oder Durchflussfähigkeit erfordern.

- Andere Industriezweige:Wird in Keramik, Feuerfeststoffen und im Recycling von industriellen Nebenprodukten in granulare Formen verwendet.

Arbeitsprozess

Der kontinuierliche mechanische Zyklus besteht aus folgenden Stufen:

1. FütterungDas Pulvermaterial wird über einen Schraubförderer gleichmäßig in den Hopfer eingespeist.

2. Verdichtungszone:Das Material dringt in die Lücke zwischen den gegenläufigen Rollen ein.

3. Hochdruck-Extrusion:Rollen üben einen extremen Druck aus, um Material in feste Blätter zu verdichten.

4. Blechform:Verdichtetes Material kommt als gemusterte Blätter/Bänder heraus.

5. Zersplitterung/Größen:Die Blätter werden in Fragmente zerbrochen und auf einheitliche Granulate gefiltert.

6. Recycling:Feinstaub und übergroße Partikel werden auf Null-Abfall verarbeitet.

7. Endprodukt:Einheitliche Granulate werden zur Verpackung/Verarbeitung entsorgt.

Für eine bessere Granulatqualität kann diese Ausrüstung mit einer Kugelformmaschine kombiniert oder in komplette automatisierte Produktionslinien integriert werden.

Einzelheiten zum Produkt

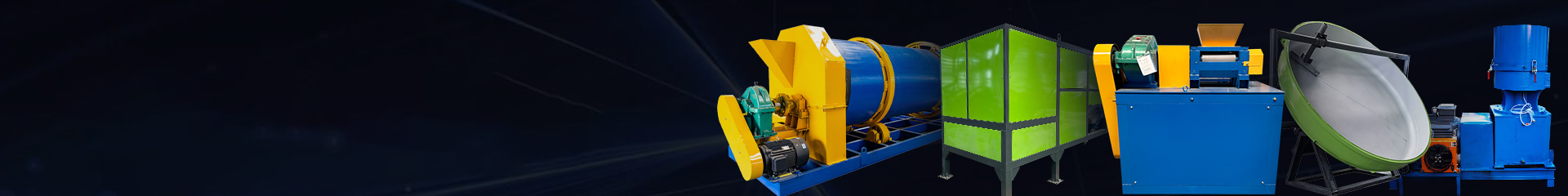

Vollständige Produktionslinie für Doppelroll-Extrusionsgranulation

Über uns

Gaofen Machinery ist ein führender Anbieter von landwirtschaftlichen Anlagen, der weltweit umfassende Produkte und Dienstleistungen anbietet:

- Lieferung von landwirtschaftlichen Geräten:Vollständige Maschinen für die Düngemittelproduktion, einschließlich Granulatoren, Brechmaschinen, Mischer, Trockner und vollständige Produktionslinien.

- Fachtechnischer Support:Professionelle Beratung bei der Auswahl der Ausrüstung und bei der Prozessoptimierung.

- Installation und Inbetriebnahme:Professionelle Einrichtung, die eine optimale Ausrüstungsleistung gewährleistet.

- Umfassende Ausbildung:Individuelle Programme für Betriebs- und Wartungsfähigkeiten.

- Zuverlässiger Kundendienst:Wartung, Fehlerbehebung und Original-Ersatzteilversorgung.

- Individuelle Lösungen:Personalisierte Ausrüstung und Produktionslinien für spezifische Anforderungen.

Kontaktieren Sie uns noch heuteSie können sich für eine Partnerschaft entscheiden und erfahren, wie unsere innovativen landwirtschaftlichen Maschinen Ihren Erfolg vorantreiben können.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!